Edge banding hot melt adhesive is a kind of adhesive specially used for pasting wood-based panels. It is an environmentally friendly, solvent-free thermoplastic adhesive. When the hot melt adhesive is heated to a certain temperature, it changes from a solid state to a molten state. When it is applied to the surface of the wood-based panel substrate or edge banding material, it cools down and becomes solid, bonding the material and the substrate together.

Advantages of PVC edge banding glue:1. The solid content is 100%, and it has gap-filling properties, which avoids the disadvantages of deformation, dislocation and shrinkage of the adhered parts caused by edge curling, air bubbles and cracking. Because there is no solvent, the moisture content of wood does not change, and there is no danger of fire and poisoning. 2. Fast bonding, the interval between gluing and bonding is only a few seconds, the saw head and trimming can be completed within 24 seconds, no drying time is required, and it can be used in continuous and automated wood bonding lines, greatly improving production Efficiency, save the factory cost. 3. Wide application, suitable for bonding various materials. 4. It can be bonded several times, that is, hot melt adhesive is applied to the wood. When it does not meet the requirements due to cooling and solidification, it can be reheated for secondary bonding. 5. There are high temperature, medium temperature, low temperature and other furniture edge sealing hot melt adhesives to choose from.

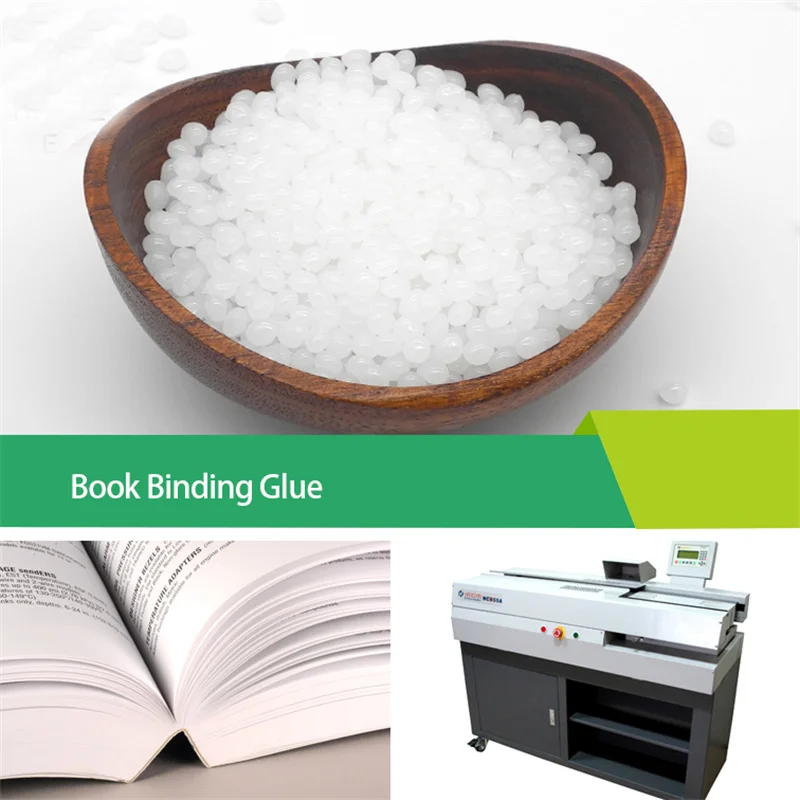

The colors of hot melt adhesives for book binding are milky white, transparent, light yellow, beige translucent, and dark yellow. Hot melt adhesives for books and periodicals are divided into edge glue and back glue according to their usage. Edge glue: Adhesive surface, generally needs to be softer than back glue, and the color requirement is not high. High viscosity requirements. Adhesive: The color requirements are slightly higher. And the hardness requirement is larger. According to the shape: cylindrical granules, round granules, and blocks are mostly three types. Generally speaking, the yellower the hot melt adhesive for bookbinding, the stronger its viscosity.

The specifications of hot-melt glue sticks commonly used in the market are basically two types with a diameter of 11.2 mm ± 0.3 and 7 mm, and a length of 200 mm to 300 mm.

Appearance color: There are yellow, light yellow, white, translucent, fully transparent and other products.

Softening point: from 65°C to 135°C.

Shear strength: from 3 MPa to 8 MPa,

Peel strength: from 50N/cm to 150 N/cm.

Melt viscosity: 5300cps

Operating temperature: 160°C—180°C

Curing time: 8-10 seconds

Product Description

Details Images

Q1: Are you a manufacturer or trading company?

A1: We are a professional manufacturer. Our newly built factory scale is good in this field. Warmly welcome to visit

us!

Q2: What are your main products?

A2: Our factory is professional in manufacturing all kinds of furniture edge banding including PVC, Acrylic, Melamine etc., as

well as profile products such as T molding, U molding etc.

Q3: How about your after-sale service?

A3: Any quality issue will get our prompt attention. Production will be reproduced for free without conditions after quality

issues’ confirmation by both sides.

Q4. What about the sample lead time?

A4: If you can send us your samples, we can copy and produce for you to test quality and color matching. Samples will be ready

within 10-14 days.

Q5. How do you ship the goods and how long does it take to arrive?

A5.We usually ship by sea. Airline is also optional.

Q6. Is it OK to print my logo on carton?

A6: Yes. Please inform us formally before our production and confirm the design firstly.

技术支持:沈阳云端科技有限公司